Categories

Festo Didactic - Your partner for technical competence development

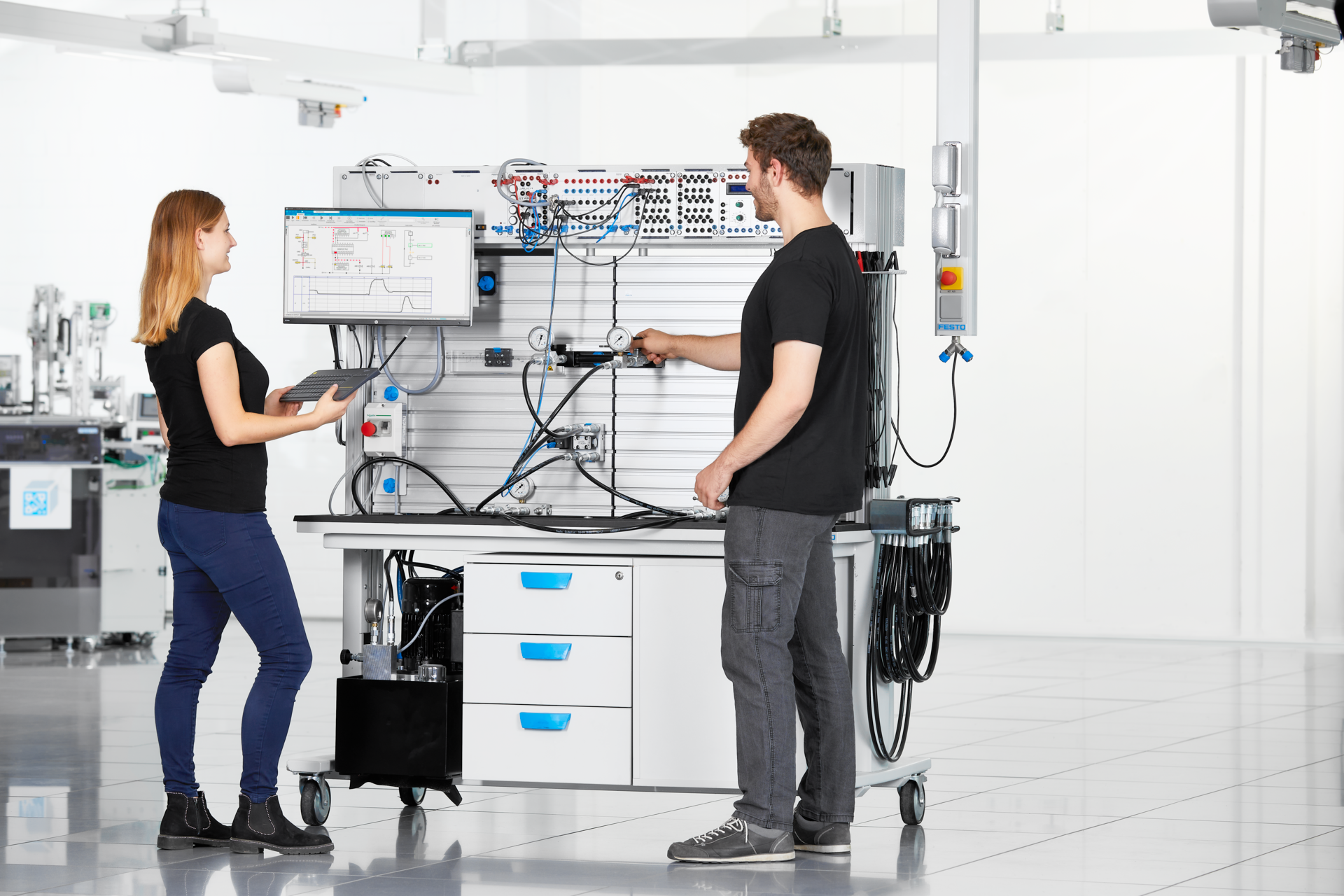

Investing in the qualification of skilled workers is the foundation for employability, productivity, innovation and sustainable growth. For this reason, we have partnered with Festo to offer state-of-the-art learning solutions in the field of technical basic and further training, to help leaners, education managers and professionals alike to develop relevant skills across all industries.

LEARNING SOLUTIONS OFFERED

Industrial Hydraulic Training

This 4-day class includes highly interactive training that blends learning, discussion, skills practice, and practical application hands-on exercises to ensure the transfer of competencies and techniques into the work environment.

To promote a comfortable learning atmosphere and limit distractions, the class size will not exceed 12 attendees.

When: March 25th thru 28th, 2025

Where: Ralph W. Earl Company | 5930 East Molloy Road | Syracuse, NY

Cost: $2,050 per participant (lunch provided daily)

Course Content:

Industrial Hydraulics

• Properties of fluid, flow, pressure & force

• Hydraulic components & their functions

• Equipment and circuit diagram symbols

• Cylinders, motors & valve types

• Solenoid valve operation

Results Realized:

• Design, assemble, and test basic hydraulic circuits

• Understand graphical symbols for hydraulic components

• Set the pressure & flow of hydraulic components & systems

• Construct circuits with valves of all varieties & activation types

Maintenance and Troubleshooting of Hydraulic Systems

• Common fail points & component maintenance

• Preventive maintenance & fluid quality management

• Cavitation causes & preventive measures

• Preventive & predictive maintenance of hydraulic circuits

• Troubleshooting components & hydraulic circuits

Results Realized:

• Identify common component fail points

• Maintain a hydraulic system and components

• Apply the principles and documentation for systematic troubleshooting in hydraulic circuits

Industrial Pneumatic Training

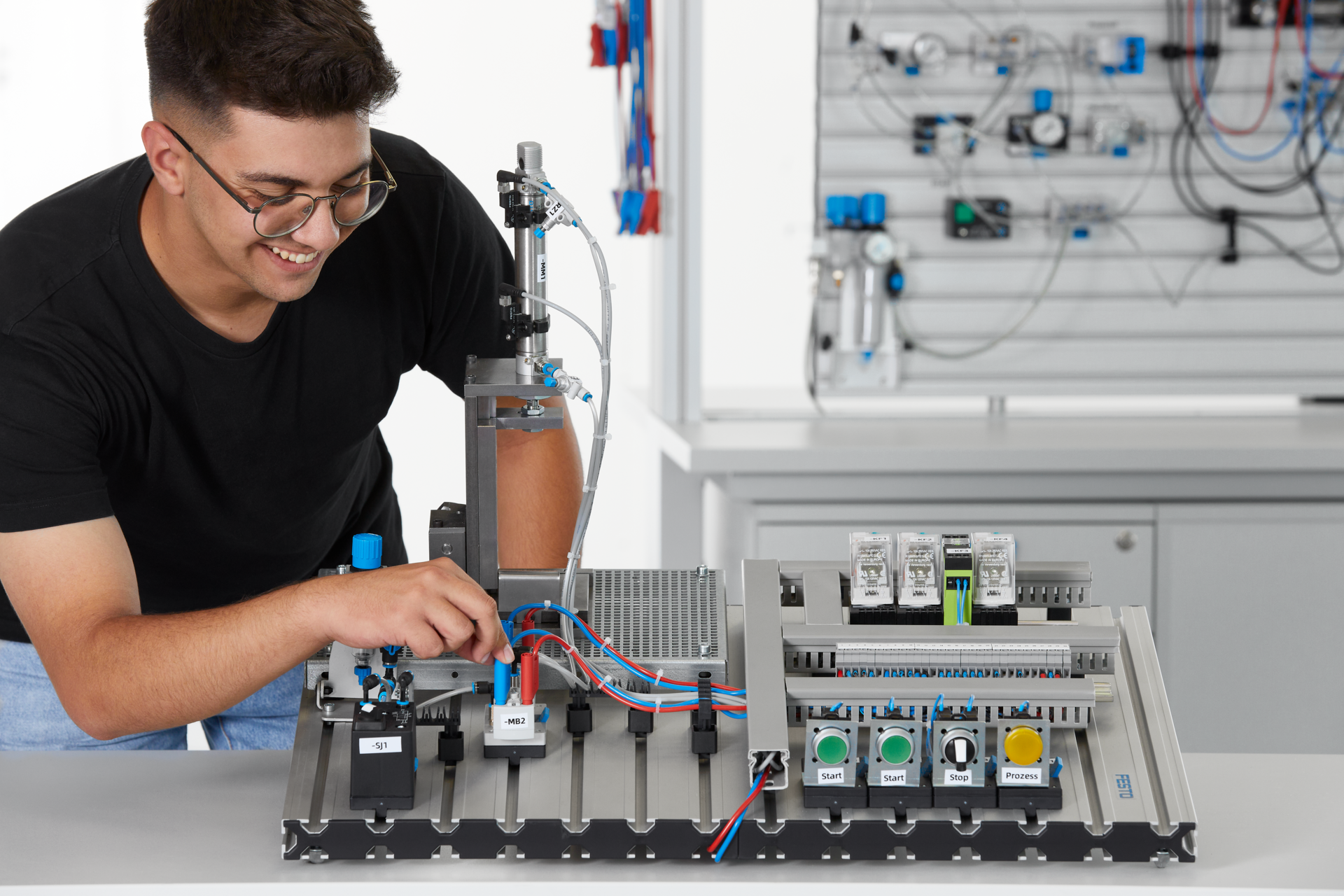

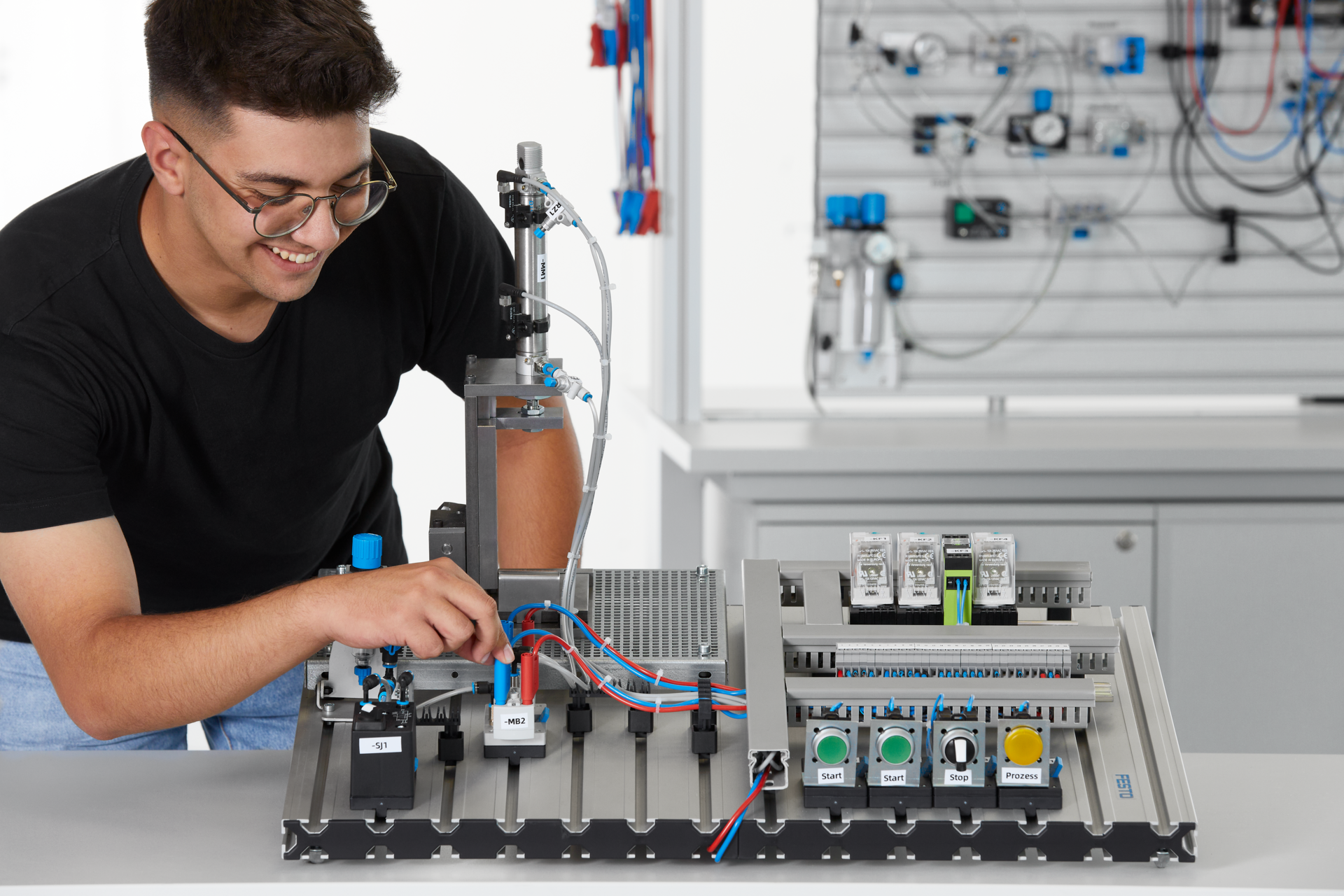

This 4-day class includes highly interactive training that blends learning, discussion, skills practice, and practical application hands-on exercises to ensure the transfer of competencies and techniques into the work environment.

To promote a comfortable learning atmosphere and limit distractions, the class size will not exceed 12 attendees.

When: April 7th thru 10th, 2025

Where: Ralph W. Earl Company | 5930 East Molloy Road | Syracuse, NY

Cost: $2,050 per participant (lunch provided daily)

Course Content:

Industrial Pneumatics

• Basic concepts of pneumatics• Fundamentals of compressed air supply: production, preparation & distribution

• Directional control valves: various types (pneumatically/electrically controlled, designs, different mid-positions, etc.)

• Shut-off valves, flow control valves, pressure valves, valve combinations

• Pneumatic and electric control of valves; position, speed, logic, pressure & time dependent control

Results Realized:

• Understands the fundamentals of compressed air generation

• Identify and explain symbols of pneumatic components

• Design, assemble, simulate & test basic pneumatic and electro-pneumatic circuits

• Maintain & troubleshoot basic pneumatic components and control systems

Maintenance and Troubleshooting of Pneumatic Systems

• Maintenance in pneumatic systems

• Troubleshooting of various pneumatic circuits

• Common failures of components

• Characteristics and behaviors of failing components

• Disassembly, inspection, and repair of failed components

• Identifying root causes of component failures

• Introduction to Failure Mode & Effect Analysis (FMEA)

Results Realized:

• Set up and commission complex pneumatic & electro-pneumatic systems

• Interpret the documentation of the system

• Interpret the construction, design features & operation of components & their relations

• Apply a methodology to troubleshoot an electro-pneumatic system

• Design & analyze a machine fault list

• Identify irregularities in pneumatic systems

• Apply FMEA to prevent failure on a system

GRANT OPTIONS AVAILABLE

Office of Strategic Workforce Development

https://esd.ny.gov/sites/default/files/OSWD-Capital-Grant-Program-Guidelines.pdf

Registered Apprenticeship Program

https://dol.ny.gov/apprenticeship/overview

Employee Training Incentive Program

https://esd.ny.gov/employee-training-incentive-program

On-the-Job Training Program

https://knowledge.nyserda.ny.gov/display/PUBLIC/Submit+an+On-the- Job+Training+Application#:~:text=NYSERDA%E2%80%99s%20On-The-Job%20Training%20for%20Energy%20Efficiency%20and%20Clean,like%20to%20hire%20and%20bring%20through%20the%20program